More progress. Mostly baby steps. I'm still looking at it as if I'm eating the elephant...one bite at a time. It was 103f today. It's 8:30 at night, and its still 98f.

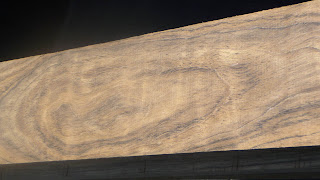

The entire stock of hardwood has been rough cut to size. These pieces will require more work to create the mortises and tenons. But the hard part is done. On too some planing/jointing/mortising/tenoning/sanding. Ugh, maybe the hard part isn't done. :)

I noticed one unfortunate problem with my $120 portable table saw. The metal insert isn't flush with the table. When cutting 45 degree angles, this causes my smaller pieces to be cut narrower then planned, as they dropped down a bit. You can also see that the top is not wearing very well. More reason to invest in a 6car garage so I can have a real solid all metal top cabinetry table saw. So instead of $120.oo, I'll need about $300,000.oo for a new house and $3,000 for the table saw. $303,000 or $120? I'll make do I suppose. Time to shim it (and it wouldn't hurt to make a zero clearance plate too) and maybe wax the table top or something.

I just love this hardwood. I took some scrap and added some clear semi-gloss...oh my, it's got serious character with amazing gold bands of quilt that you just cant see on the unfinished wood.

I should also mention that this stuff is insanely heavy. We may not be able to move this chest (empty) once it's completed. Time to think about rigging it with those rubber roller blade wheels. Maybe an electric motor and a steering wheel too.

Thanks for reading.